Industrial Parts Cleaning

- Naturally the better solution!

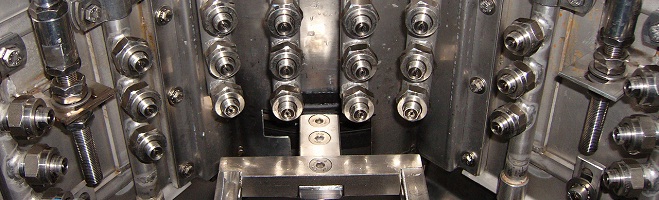

Rotary indexing table systems

In a rotary indexing system, the parts to be washed go successively through the various processing stations in a circle, taking up very little space. This makes the loading position identical to the unloading position, which can be handled by a single robot or any other kind of automation system. The compact design means the system can be used as a decentralized washing solution, e.g. immediately alongside a processing centre. Such a system stands out for high washing quality at short cycle times.

Special features:

- Single and multiple-stage methods for washing and rinsing, blow-off, and hot-air drying and/or cooling

- Fully shielded handling zones

- Minimal space requirements through compact and optimized design

- Entirely stainless steel construction, heat insulated with polished cassettes

- Highest quality components and aggregates from European manufacturers

- Conveyor system with specific holders for precise positioning

- Goods movement in all treatment zones

- Perfectly suited to complex workpiece geometries (undercuts, blind holes, drill holes, etc.)

- CAD-optimized spray pattern

Optional features:

- Process monitoring (throughput, pressure, conductance, pH, etc.)

- Filter equipment

- Steam condenser (air and water-cooled)

- Oil separator

- Dosing system

- Inspection window and interior lighting

- Additional rinsing baths

- Wastewater piping and wastewater pump

- Floor tray with leak warning sensor

- Vacuum drying

- Remote maintenance

- Heating by integrated heat exchangers (hot water, steam)

Learn more?

- Your contact person:

- Markus Weber

- Phone: +49 (0)9129 4099-88

- Fax: +49 (0)9129 4099-988

- e-mail: wm@semmelroth.de