Industrial Parts Cleaning

- Naturally the better solution!

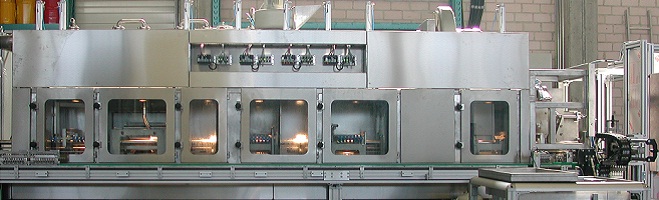

Linear indexing systems

Indexing systems based on linear systems have additional advantages. Precise positioning of the washed parts allows problem zones and difficult geometries to be worked, e.g. blind holes, threaded holes or undercuts. Furthermore, channels can be adapted to allow complete rinsing. Reuse of carriers also allows families of components to be washed in the same system. Full integration into production lines, including automated loading and unloading, e.g. by robot, completes an optimal processing system.

Special features:

- Single and multi-stage processes with up to 3 baths

- Fully stainless steel construction

- Highest quality components and aggregates from European manufacturers

- Variable conveying system (belt, chain or overhead conveying) with optional return

- Recirculating air drying with blower

- Zone separation with lifting doors

Optional features:

- Process monitoring (throughput, pressure, conductance, pH, etc.)

- Filter equipment

- Steam condenser (air and water-cooled)

- Oil separator

- Dosing system

- Inspection window and interior lighting

- Additional rinsing baths

- Wastewater piping and wastewater pump

- Floor tray with leak warning sensor

- and much more...

Help with selection according to component size+ more content

|

Länge |

||||||||

|---|---|---|---|---|---|---|---|---|

| Breite |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

Höhe |

| 200 |

S 602 |

S 612 |

S 622 |

S 632 |

S 642 |

S 652 |

S 662 |

200 |

| 300 |

S 603 |

S 613 |

S 623 |

S 633 |

S 643 |

S 653 |

S 663 |

300 |

| 500 |

S 605 |

S 615 |

S 625 |

S 635 |

S 645 |

S 655 |

S 665 |

400 |

| 700 |

S 607 |

S 617 |

S 627 |

S 637 |

S 647 |

S 657 |

S 667 |

500 |

Technical data, with S 623/2 as example+ more content

| Abmessungen (LxBxH) [mm] |

4800 x 1880 x 1950 |

| Volumen Bad 1 [Liter] |

660 |

| Heizleistung Bad 1 [KW] |

18 |

| Volumen Bad 2 [Liter] |

440 |

| Heizleistung Bad 2 [KW] |

12 |

| Gebläseleistung [KW] |

5,5 |

Learn more?

- Your contact person:

- Markus Weber

- Phone: +49 (0)9129 4099-88

- Fax: +49 (0)9129 4099-988

- e-mail: wm@semmelroth.de